Siemens PLC

MOQ : 1 , , Piece

Siemens PLC Specification

- Screen Size

- Integrated 7-inch display (for relevant models) Meter (m)

- Mounting Type

- DIN Rail

- Features

- Realtime data logging, Web server, Expandable I/O, Modular design

- Frequency

- 50/60 Hz Hertz (HZ)

- Drive Type

- Solid State Relay / Mechanical relay (optional)

- IP Rating

- IP20

- Connectivity Type

- Ethernet, RS232, RS485, Profibus

- Control Type

- Microprocessor based

- Load Capacity

- Configurable, up to 6A per output Long Ton

- Processor Type

- Siemens proprietary CPU (S7 Series)

- Automation Grade

- Automatic

- Weight

- Approx. 1.5 kg Kilograms (kg)

- Cable Length

- Standard: 1 meter, extendable Meter (m)

- Remote Control

- Yes

- Phase

- Single / Three Phase

- Speed Range

- Programmable

- Sensor Type

- Supports analog and digital sensors

- Application

- Industrial Automation, Process Monitoring, Machine Control

- Material

- Premium Industrial ABS Plastic and Metal

- Power

- 24 V DC Volt (v)

- Temperature

- 0C to 60C operating Celsius (oC)

- Voltage

- 24 VDC / 230 VAC Watt (w)

- Number of Inputs

- Up to 32 digital, 16 analog (expandable)

- Programming Language

- Ladder Logic, Function Block, Structured Text

- Output Type

- Transistor / Relay

- Expansion Module Support

- Yes, for Digital and Analog I/O

- Response Time

- <1 ms (fast application processing)

- Protection

- Overvoltage, short-circuit, thermal protection

- Communication Protocols

- Modbus, Profinet, TCP/IP

- Clock

- Real Time Clock (RTC) included

- Display Type

- Backlit LCD for relevant models

- Supply Current

- 0.5A to 10A, model-dependent

- Diagnostics

- Integrated self-diagnostics and status LED

- Programming Interface

- TIA Portal, Step 7

- Number of Outputs

- Up to 32 digital, 8 analog (expandable)

- Memory Capacity

- Up to 512 KB (depending on model)

- Data Storage

- Integrated Flash Memory

Siemens PLC Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 2-5 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Carton PAckaging

- Main Export Market(s)

- South America, Western Europe, Middle East, Central America, Africa, Asia, Eastern Europe, North America, Australia

- Main Domestic Market

- All India

About Siemens PLC

Select the extraordinary Siemens PLC with Expansion Module Support, engineered for dazzling performance in demanding industrial automation environments. Take advantage of up to 32 digital and 16 analog inputs, expandable as your process grows. Featured with integrated flash memory, real-time clock, and self-diagnostics, this crackerjack controller offers rapid response times (<1 ms) for swift application processing. Program seamlessly with TIA Portal, Step 7, and multiple languages. Embrace premium durability in ABS and metal, robust protection features, web server capabilities, and versatile connectivity including Ethernet, RS232, and Profibus. Built to empower your automation needs.

Diverse Applications and Exceptional Versatility

The Siemens PLC excels in both specific and general industrial automationfrom process monitoring to sophisticated machine control. Used as a central processing unit in automatic factories, it expertly manages multiple digital and analog I/Os, accommodating dynamic production demands. Designed for seamless integration, it supports various sensor types and drives, making it indispensable for sectors such as manufacturing, packaging, or energy. Its robust construction ensures reliable use in challenging environments, delivering dependable automation with ease.

Flexible Payment, Strong Export Markets, and Reliable Supply

Experience hassle-free payment terms for your Siemens PLC orders, tailored to accommodate various client requirements and proposal amounts. With a strong export presence, Siemens reaches major markets across Asia, Europe, and the Middle East. Each shipment is processed promptly and tracked for your convenience, ensuring client satisfaction and sustained market value. Our impressive supply capacity meets bulk and custom demands efficiently, maintaining a steady inventory for both short- and long-term industrial projects.

Diverse Applications and Exceptional Versatility

The Siemens PLC excels in both specific and general industrial automationfrom process monitoring to sophisticated machine control. Used as a central processing unit in automatic factories, it expertly manages multiple digital and analog I/Os, accommodating dynamic production demands. Designed for seamless integration, it supports various sensor types and drives, making it indispensable for sectors such as manufacturing, packaging, or energy. Its robust construction ensures reliable use in challenging environments, delivering dependable automation with ease.

Flexible Payment, Strong Export Markets, and Reliable Supply

Experience hassle-free payment terms for your Siemens PLC orders, tailored to accommodate various client requirements and proposal amounts. With a strong export presence, Siemens reaches major markets across Asia, Europe, and the Middle East. Each shipment is processed promptly and tracked for your convenience, ensuring client satisfaction and sustained market value. Our impressive supply capacity meets bulk and custom demands efficiently, maintaining a steady inventory for both short- and long-term industrial projects.

FAQs of Siemens PLC:

Q: How can I expand the input and output capacity of the Siemens PLC?

A: The Siemens PLC supports modular expansion, allowing you to add extra digital and analog input/output modules as your control requirements increase. This extension is easy to implement and can be configured via the TIA Portal or Step 7 programming environments.Q: What types of programming languages are compatible with this PLC?

A: You can program the Siemens PLC using Ladder Logic, Function Block, or Structured Text, offering flexible control strategies to suit different application needs and technical expertise levels.Q: When should I consider utilizing the integrated web server feature?

A: The integrated web server is particularly beneficial when remote monitoring and real-time data logging are required. It enables authorized users to access system statuses, diagnostic data, and performance metrics from a standard web browser, increasing overall control and visibility.Q: Where can this PLC be mounted, and what environments does it support?

A: This PLC is designed for DIN rail mounting and is constructed with premium ABS plastic and metal for industrial durability. Its IP20 rating and robust protection features make it suitable for controlled-environment industrial automation within a temperature range of 0C to 60C.Q: What are the key advantages of using the Siemens PLC in automation projects?

A: Key benefits include extraordinarily fast response times, expansive I/O capabilities, integrated diagnostics, robust communication protocols, and flexible sensor support. These features combine to offer exceptional process control, reduced downtime, and simplified system maintenance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Electrical Automation Product Category

Simatic SP 200 PLC

Price Range 20000.00 - 50000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Weight : Approx. 350g

Mounting Type : DIN Rail Mounting

Remote Control : Yes

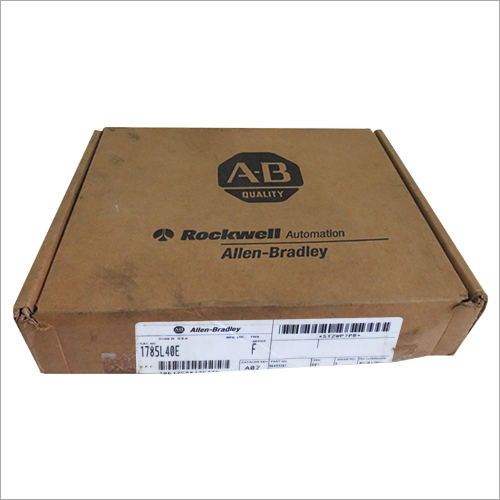

1785 L40E-F Allen Bradley Ethernet Module

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 1.5 kg (Approx.)

Mounting Type : Rack Mount

Remote Control : Yes

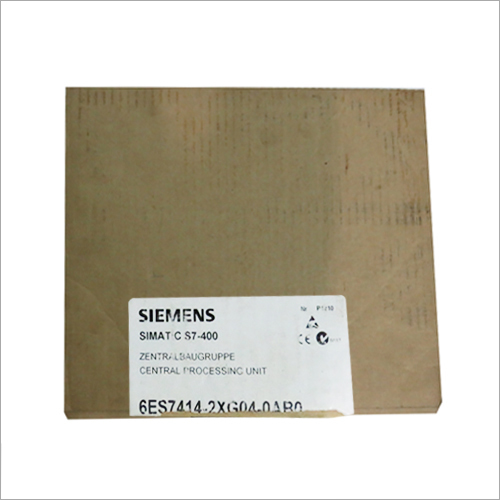

6ES7414-2XG04-0AB0 Siemens

Price 10000 INR / Piece

Minimum Order Quantity : 1 , , Piece

Weight : Approx. 480 g Grams (g)

Mounting Type : Rack Mount (S7400 rack)

Remote Control : Yes

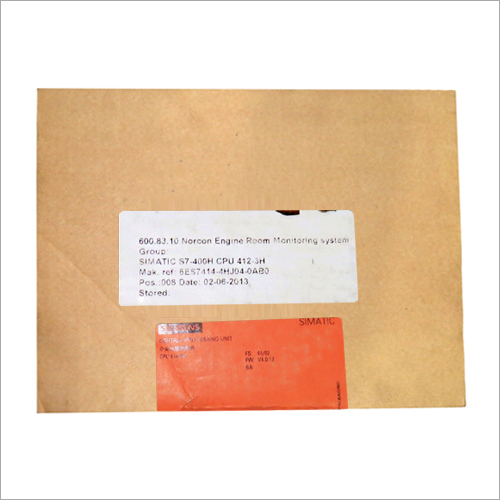

6ES7 414-4HJO4-OAB0 Siemens 414 CPU

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : Approx. 900 g

Mounting Type : Rack Mount (S7400 Rail)

Remote Control : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS